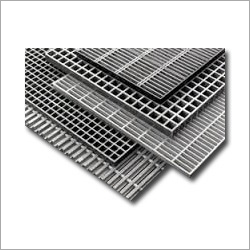

GI Gratings

Price 65000 INR/ Metric Ton

MOQ : 10 Metric Tons

GI Gratings Specification

- Shape

- Rectangle

- Material

- Other

- Application

- Industrial Flooring, Stair Treads, Walkways

- Surface Treatment

- Galvanized

- Color

- Silver

GI Gratings Trade Information

- Minimum Order Quantity

- 10 Metric Tons

- Supply Ability

- 1000 Metric Tons Per Month

- Delivery Time

- 1-2 Days

About GI Gratings

We are offering here the GI Gratings that are ideal for storing heavy duty goods and loads placed in the middle of a shelf. The Gratings allow light, air, and water from the sprinkler system to protect goods and equipment. The gratings are a special form of heavy-duty grating and find application primarily as vehicle access covers that enable vehicles to deposit or off-load bulk materials. The main characteristics of gutter gratings are their high load-bearing capacity, coupled with their functional bulk goods permeability. The offered GI Gratings are efficient and made for easy to install.

Unmatched Durability and Protection

Our GI Gratings undergo a comprehensive galvanization process, providing an extra layer of protection against rust and corrosion. This ensures they remain structurally sound and visually appealing even in challenging industrial environments. The rectangular design further enhances their load-carrying capacity, making them an ideal choice for high-traffic areas like factory floors and outdoor walkways.

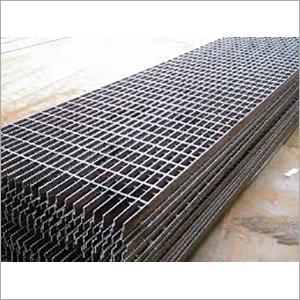

Versatile Applications for Industrial Needs

Engineered for industrial flooring, stair treads, and walkways, these silver-colored GI Gratings are versatile enough to handle various operational requirements. Their design focuses on safety and slip resistance, making them suitable for use in factories, plants, warehouses, and chemical processing areas. As trusted suppliers and service providers, we deliver tailored solutions across India and global markets.

FAQs of GI Gratings:

Q: How are GI Gratings manufactured for industrial applications?

A: GI Gratings are produced using a rigorous fabrication process that includes welding or pressure locking, followed by dipping the product in molten zinc to achieve thorough galvanization. This results in a robust, corrosion-resistant structure ideal for industrial flooring, stair treads, and walkways.Q: What are the advantages of using galvanized surface-treated gratings?

A: Galvanized surface treatment provides superior protection against rust, chemical exposure, and moisture, significantly extending the lifespan and reducing maintenance needs. This makes them especially beneficial for harsh industrial environments.Q: Where can these rectangular GI Gratings be installed?

A: These gratings are primarily used in industrial flooring, stair treads, and walkways. They can be installed in factories, production units, chemical plants, warehouses, and areas requiring sturdy, anti-slip surfaces.Q: When should I consider replacing existing flooring with GI Gratings?

A: Its advisable to replace old or corroded flooring with GI Gratings when you notice reduced structural integrity, an increase in maintenance costs, or safety hazards due to rust or damage. The galvanized finish offers a long-term, cost-effective upgrade.Q: What is the process for ordering customized GI Gratings from your company?

A: Contact our team with your specific requirements regarding dimensions, load capacity, and application. We provide design consultation, fabrication, and on-time delivery, catering to clients both in India and internationally.Q: How do GI Gratings benefit industrial operations?

A: They provide a safe and stable walking or working surface, improve load distribution, and minimize slip risks. The galvanized coating ensures durability, which translates into long-term cost savings and fewer operational disruptions.Q: What materials are used in your GI Gratings besides iron?

A: Our GI Gratings are primarily manufactured using high-quality steel, treated with galvanization for enhanced strength and corrosion resistance. This ensures optimal performance in industrial settings.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in GI Gratings Category

Bar Gratings

Price 82000 INR / Metric Ton

Minimum Order Quantity : 10 Tons

Application : Flooring, Walkways, Stair Treads, Platform

Color : Silver

Usage : Industrial

Width : Varies Centimeter (cm)

Steel Gratings

Price 65000 INR / Metric Ton

Minimum Order Quantity : 1 Kilograms

Application : Industrial Flooring, Walkways, Platforms

Color : Silver

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS